Though we will be exploring the regulation of clinical next generation sequencing (NGS) products in this article, it’s necessary to first talk about breast implants. Between the years of 1990 and 2010, more than two million implants were produced by the Poly Implant Prothèse (PIP) company1. Many were given to patients who sought to reclaim the body that cancer had stolen from them. Others saw the implants as cosmetic, a form of self expression akin to a new tattoo. While their reasons were each their own, they all shared a common trust that the PIP implants were safe. Few, if any, expected the chronic pain, mental anguish, and medical uncertainty that would follow.

PIP’s breast implant scandal broke in 2010 when reports of adverse events drove the French medical safety agency (Agence Nationale De Sécurité Du Médicament Et Des Produits De Santé) to recall the company’s products (with several other countries following suit). Accumulating evidence showed the implants were rupturing at more than double the expected rate, resulting in significant pain and inflammation for patients. Subsequent investigations found that the defunct implants had been synthesized using a cheap industrial grade silicone which, among other issues, can leak potentially harmful metals into the patient’s body when ruptured2-5.

Even today, the effects of the PIP implant scandal ripple across the medical community. While the European Union (EU) had regulations mandating the use of medical grade materials for such devices, the lack of regulatory oversight enabled PIP to manufacture and distribute fraudulent products for nearly a decade5. The scandal proved to be the last straw. After myriad other examples where manufacturers were found to be using misleading claims, false advertising, and counterfeit devices, the EU resolved to draft the Medical Devices Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR), two international mandates that collectively require validation and oversight of nearly all tools used in modern medicine, from implants to NGS assays6,7. Such regulation could help to put medical and in vitro diagnostic device manufacturing under a microscope and reduce the chance of fraudulent or malfunctioning devices from reaching patients.

MDR and IVDR came into effect in May of 2021 and 2022, respectively. This means that all new devices entering the EU market must be MDR or IVDR compliant. However, laboratories have been granted a transition period to either phase out existing devices or else to bring them into compliance with these new regulations. Such a process is far from simple, and clinical laboratories across the European economic area will need support from device and assay manufacturers to ensure laboratory operations continue. That’s where Twist can help.

What is IVDR?

Put simply, both MDR and IVDR are internationally recognized regulations designed to improve the quality of medical and diagnostic supplies, ultimately to better patient safety and the effectiveness of devices. MDR applies to devices that will interact with the patient’s body (such as pacemakers, implants, and contact lenses)6. IVDR governs a wide range of IVDs encompassing both hardware and software. These include familiar tools like pregnancy tests and HIV assays, but also extend to more complex technologies. Estimates suggest that 70% of clinical decisions are made using in vitro diagnostic devices8.

Prior to IVDR, the quality of most in vitro diagnostics was established through a self certification process. However, with IVDR, many such devices will need to be evaluated and certified by a notified body—a designated entity responsible for evaluating a product’s regulatory compliance. By the numbers, only about 15% of in vitro diagnostic devices currently require a notified body certification. Under IVDR, that number is expected to jump up to 70%-90%7.

As of the writing of this article, IVDR compliance for existing laboratory devices and workflows is not expected until late 2027 for high-risk devices (though that date may change with time)8. Despite this, the medical community is likely headed towards a significant bottleneck. First, labs will need to collect more rigorous clinical evidence, performance evaluations, and quality management systems than they were previously required under the In Vitro Diagnostic Medical Device Directive (IVDD). The complexity of doing so, coupled with limited Notified Body capacity, can significantly extend the time it takes to obtain IVDR certification. In turn, this transition may cause temporary shortages or delays in the availability of in vitro devices while manufacturers work to adapt to the new requirements.

Already, the bottleneck is starting to narrow. 26 de mayoth, 2024, marked a significant milestone in IVDR implementation 9. As of this date, in house devices—diagnostic devices developed and used within a laboratory—are expected to be in compliance with IVDR regulations and may be subject to audit by notified bodies. Accordingly, laboratories are under pressure to either establish the validity of in house devices, or else switch to CE certified commercial products.

Fortunately, laboratories can simplify the transition by integrating IVDR compliant products into their workflows now. Twist offers three such products, known collectively as the Twist Precision Dx Products.

🧬 The Value of Using Established IVDR Compliant Products

Laboratories will need to take steps to update their devices and workflows in order to become IVDR compliant. To do so, they can either start from scratch, or they can get a leg up by integrating products that have already been certified compliant. Many Class A devices and ancillary products (reagents, controls, calibrators) have already received the CE mark of compliance. Using these devices now can have several benefits:

- Build a Strong Foundation: Early certification of Class A products establishes a robust quality management system and regulatory compliance framework that can be leveraged for higher-class IVD certifications.

- Ease Future Regulatory Submissions: Utilizing IVDR-certified ancillary products during the development and validation of higher-class IVDs is often mandatory. Integrating them now can reduce work later.

- Accelerate Time-to-Market: A streamlined transition for Class A products can help expedite the overall certification process for the final product.

- Commitment to Quality: Early compliance demonstrates a commitment to quality and safety, enhancing your brand reputation and differentiating your products in the market.

- Customer Confidence: Customers are more likely to trust and adopt products developed using IVDR-certified components, as it provides assurance of quality, reliability, and stability through the pending bottleneck.

IVDR Compliant NGS Tools

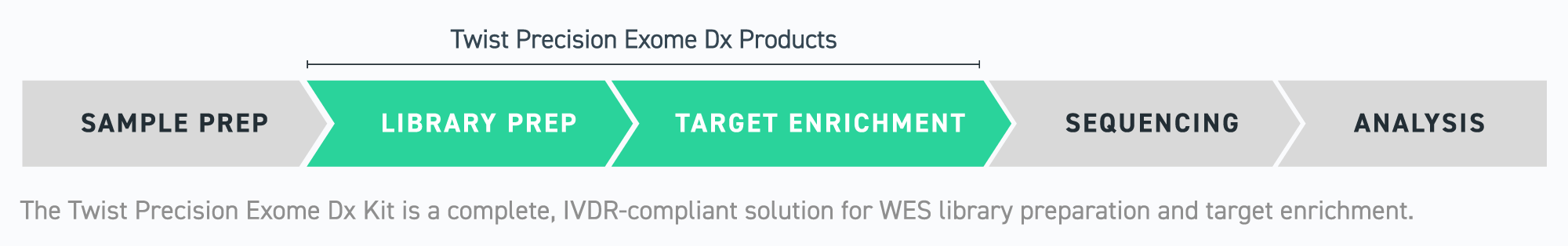

The Twist Precision Dx Products are designed to support laboratories in the European economic area as they transition to IVDR compliant (CE certified) NGS workflows. NGS is becoming an ever more important tool for clinical laboratories. Whole exome sequencing (WES) in particular is proving valuable for its ability to provide robust sequencing data across all protein coding genes with efficiency. When paired with expert analysis, WES may support a wide range of diagnostic applications as well as guide subsequent therapeutic decision making.

IVDR mandates comprehensive validation, encompassing every step of the workflow – from the collection tubes to the data analysis software. This thorough process, while crucial, can be time-consuming and involve iterative refinements. Twist Precision Dx Products, pre-validated and CE-marked, can significantly streamline this process for laboratories.

Having already been CE certified, the Twist Precision Dx Products can help to alleviate some of the pain in this process. Twist’s IVDR compliant products include:

- Kit de preparación y enriquecimiento Precision Dx Twist: Reactivos para la preparación de bibliotecas, la fragmentación enzimática y el enriquecimiento del objetivo.

- Kit de exoma Precision Dx Twist: Reagents for enzymatic fragmentation, library preparation, and target enrichment along with targeted capture probes for whole exome enrichment.

- Panel de exoma Precision Dx Twist: Targeted capture probes for whole exome enrichment.

The Twist Precision Prep and Enrichment Dx Kit provides a streamlined workflow that combines library preparation steps into a single-tube reaction which, alongside a high on-target rate and Twist’s highly uniform target enrichment workflow, enables quality library preparation and sequencing results. El kit puede utilizarse para dirigir a regiones específicas del genoma paneles de ADN suministrados por usuarios o un panel de ADN Twist cualificado (como el panel de exoma Precision Dx Twist) para aplicaciones de secuenciación de última generación (NGS).

To this end, the Twist Precision Exome Dx Panel is designed to provide robust sequencing data for a significant portion of clinically relevant loci, including >97% off the CCDS, RefSeq, Gencode and Ensembl v101 databases, as well as the mitochondrial genome.

Both products can be individually purchased by laboratories in the EU, or they can be bundled together into a single product referred to as the Twist Precision Exome Dx Kit. Together, these products have demonstrated effective performance in several quality metrics, earning them CE certification.

Additionally, to help laboratories integrate Twist IVDR compliant products in their own workflows and/or IVDR submission, Twist has partnered with Platomics and their PlatoX® IVD Assistant platform which provides users with access to Twist’s IVDR-compliant documentation. While end users will be required to validate their complete workflow, Twist’s CE-certified products are sure to reduce the burden of this process and make it easier for laboratories to set up IVDR-compliant WES workflows.

Ultimately, regulations like MDR and IVDR are intended to protect patients and prevent future events like the PIP breast implant scandal. But transitioning into a new regulatory landscape can be a turbulent process. Twist’s Precision Dx Products can help laboratories find a smoother path to compliance.

Referencias bibliográficas

- Kirsh, Danielle. “PIP Breast Implant Scandal: A Story That Triggered Change.” MassDevice, 13 Nov. 2017, www.massdevice.com/pip-breast-implant-scandal-story-triggered-change/.

- Wazir, Umar, et al. “The Clinical Implications of Poly Implant Prothèse Breast Implants: An Overview.” Archives of Plastic Surgery, vol. 42, no. 1, 2015, p. 4, https://doi.org/10.5999/aps.2015.42.1.4

- Camacho, Juan P, et al. “Squamous Cell Carcinoma as a Result of Likely Industrial Grade Ruptured Poly Implant Prosthèse Silicone Buttock Implants.” Aesthetic Surgery Journal Open Forum, vol. 2, no. 3, 6 July 2020, https://doi.org/10.1093/asjof/ojaa030.

- Kolios, Leila, et al. “Complications of Poly Implant Prothèse Breast Implants: The Current Discussion.” Expert Review of Medical Devices, vol. 10, no. 2, Mar. 2013, pp. 167–170, https://doi.org/10.1586/erd.12.87.

- Martindale, Victoria, and Andre Menache. “The PIP Scandal: An Analysis of the Process of Quality Control That Failed to Safeguard Women from the Health Risks.” Journal of the Royal Society of Medicine, vol. 106, no. 5, may de 2013, pp. 173–177, www.ncbi.nlm.nih.gov/pmc/articles/PMC3676226/, https://doi.org/10.1177/0141076813480994.

- Huusko, Juhamatti, et al. “Medical Device Regulation (MDR) in Health Technology Enterprises – Perspectives of Managers and Regulatory Professionals.” BMC Health Services Research, vol. 23, no. 1, 30 Mar. 2023, www.ncbi.nlm.nih.gov/pmc/articles/PMC10062684/, https://doi.org/10.1186/s12913-023-09316-8.

- Lubbers, Bart R., et al. “The New EU Regulation on in Vitro Diagnostic Medical Devices: Implications and Preparatory Actions for Diagnostic Laboratories.” HemaSphere, vol. 5, no. 5, 1 may de 2021, p. e568, journals.lww.com/hemasphere/Fulltext/2021/05000/The_New_EU_Regulation_on_In_Vitro_Diagnostic.2.aspx, https://doi.org/10.1097/HS9.0000000000000568

- “Commission Proposes Measures to Improve the Availability of in Vitro Diagnostics.” European Commission, European Commission, 23 Jan. 2024, ec.europa.eu/commission/presscorner/detail/en/ip_24_346.

- “EU Update: Deadline Nears for In-House Devices to Comply with IVDR.” Emergo by UL, www.emergobyul.com/news/eu-update-deadline-nears-house-devices-comply-ivdr.

¿Qué piensa?

Me gusta

No me gusta

Me encanta

Me asombra

Me interesa